Behind The Scenes - Keyboard Stands

03 September 2022

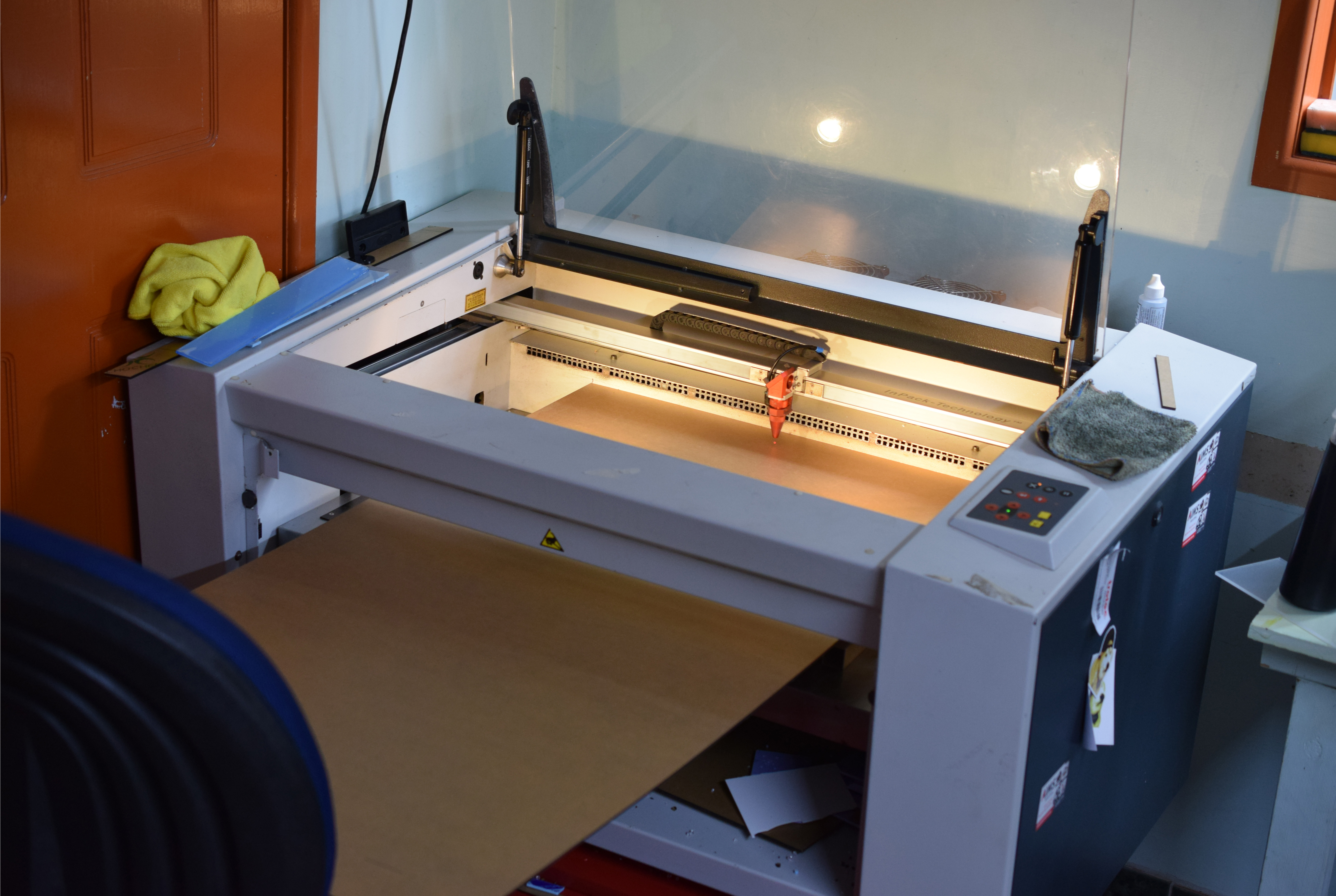

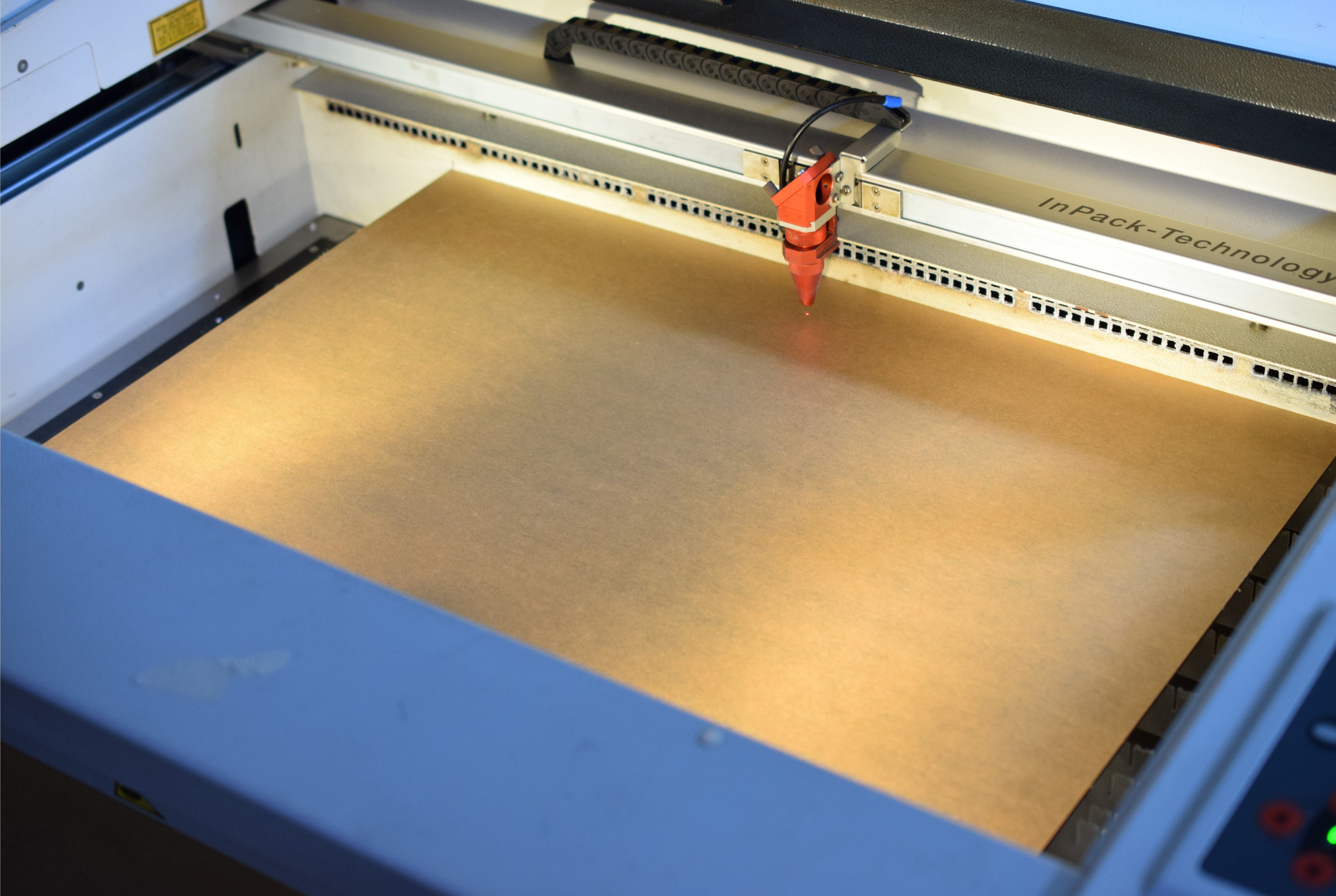

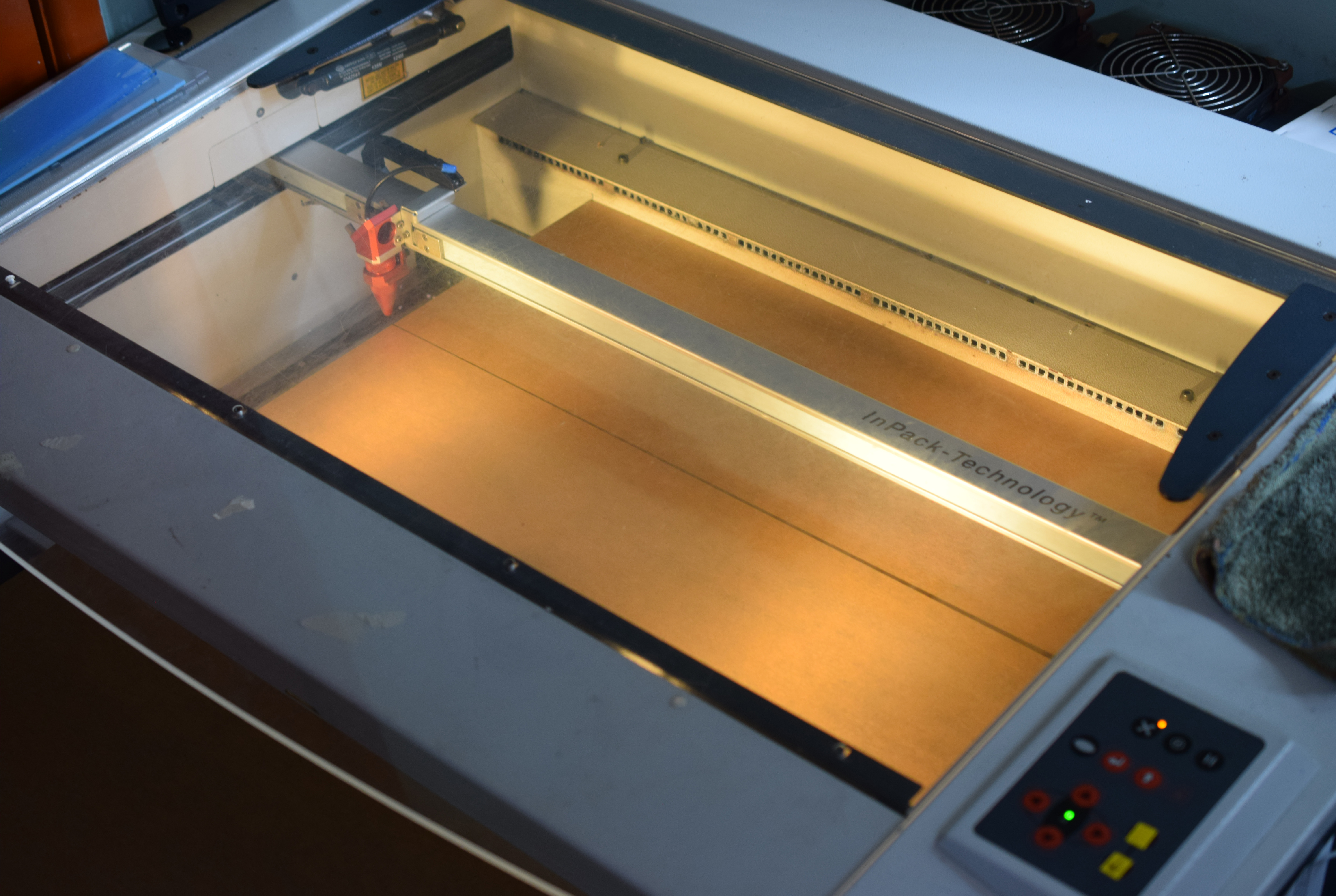

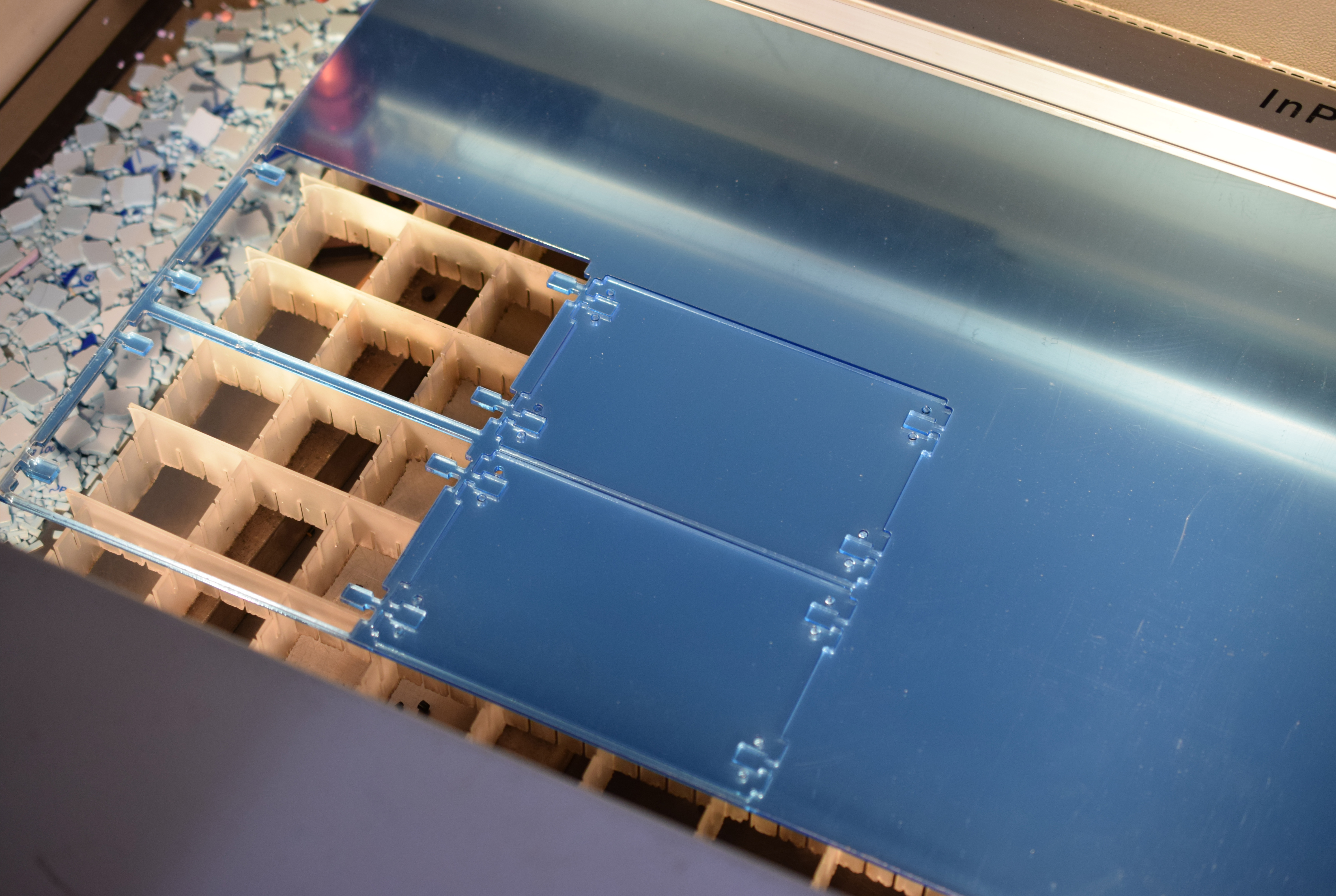

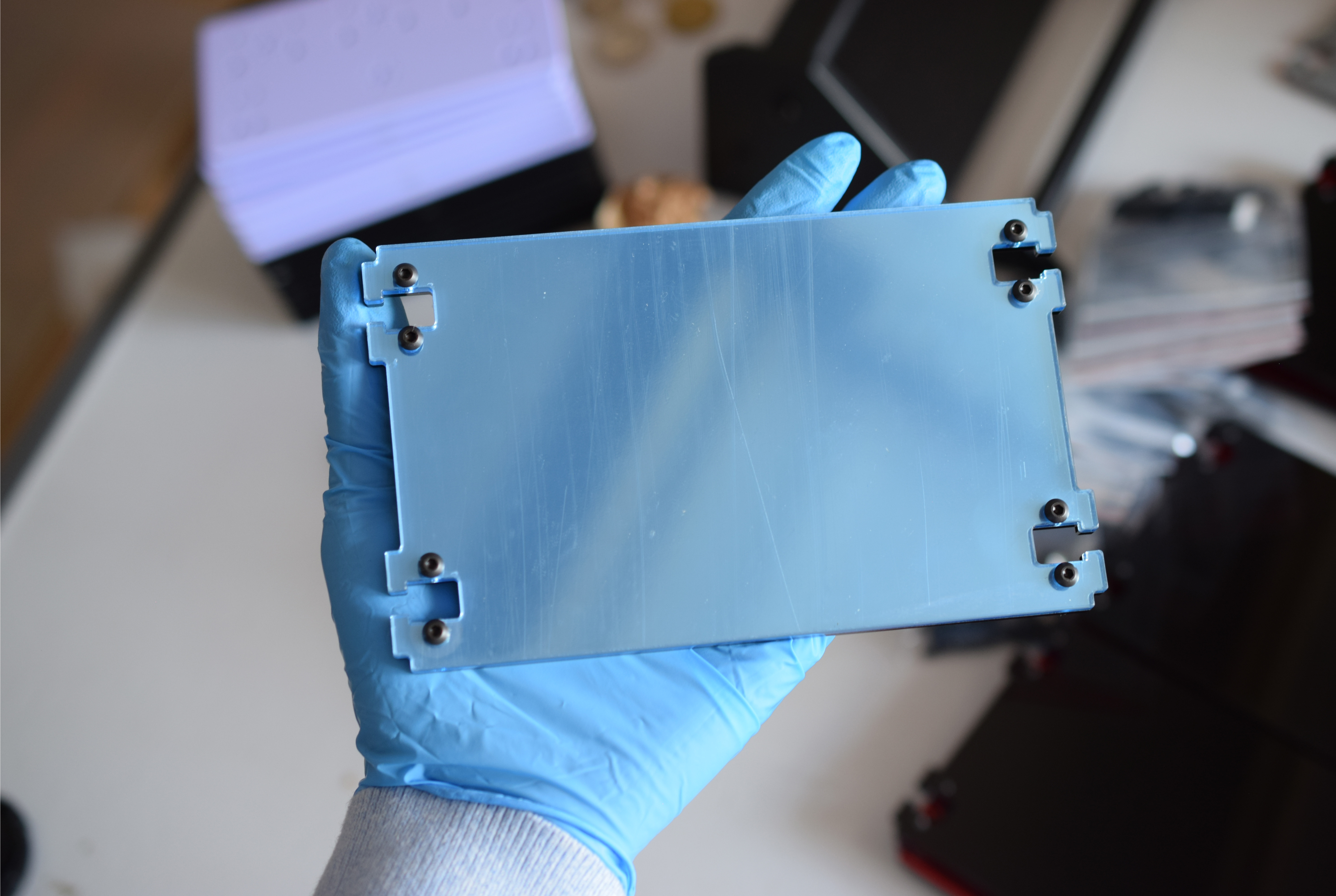

Getting the Right Sized Sheet of Acrylic

First, I start with a whole sheet of acrylic and cut it down to size. The dimensions of the newly cut sheet will depend on what is being made.

In this scenario, I need a sheet that is 22cm (H) X 60cm (L).

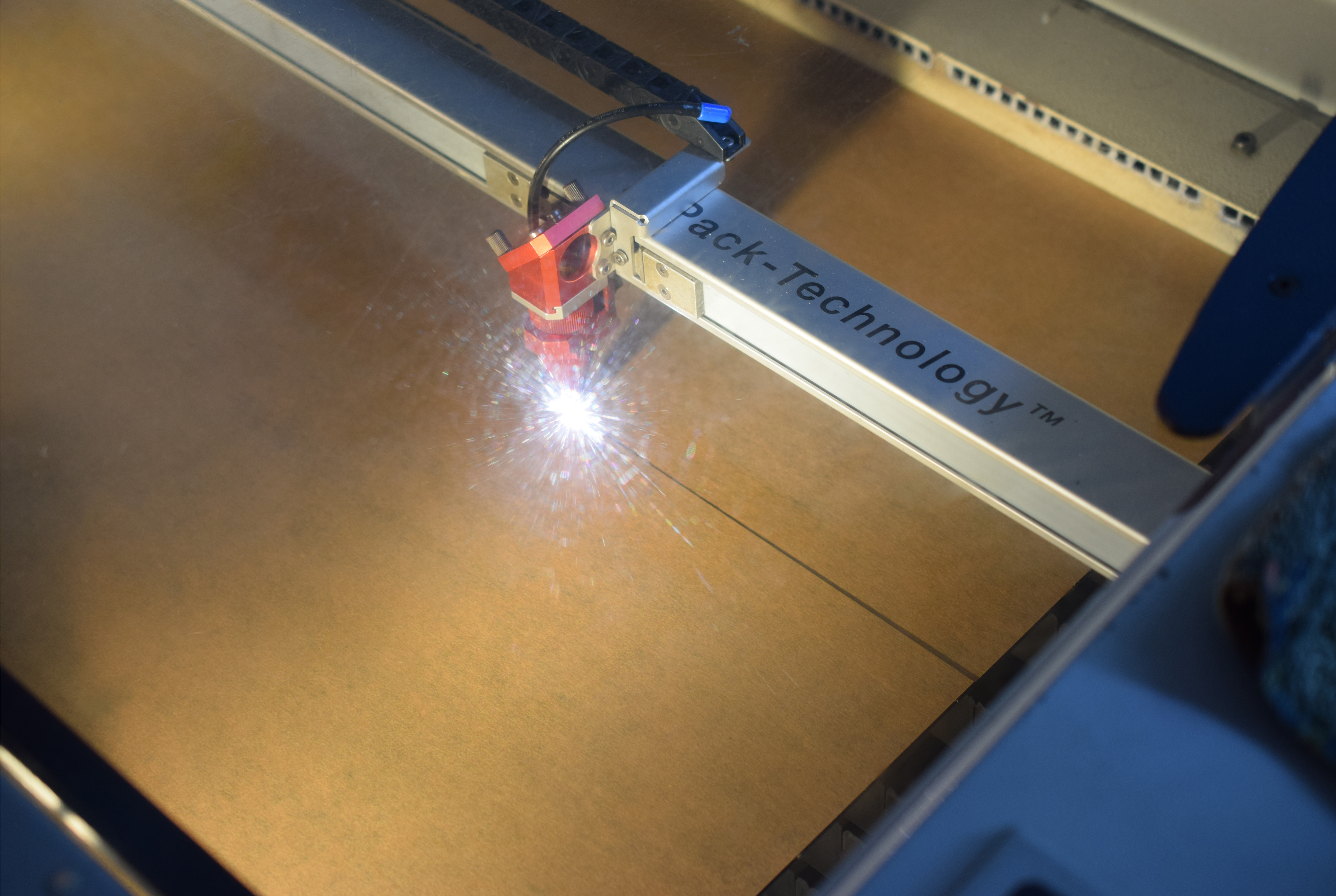

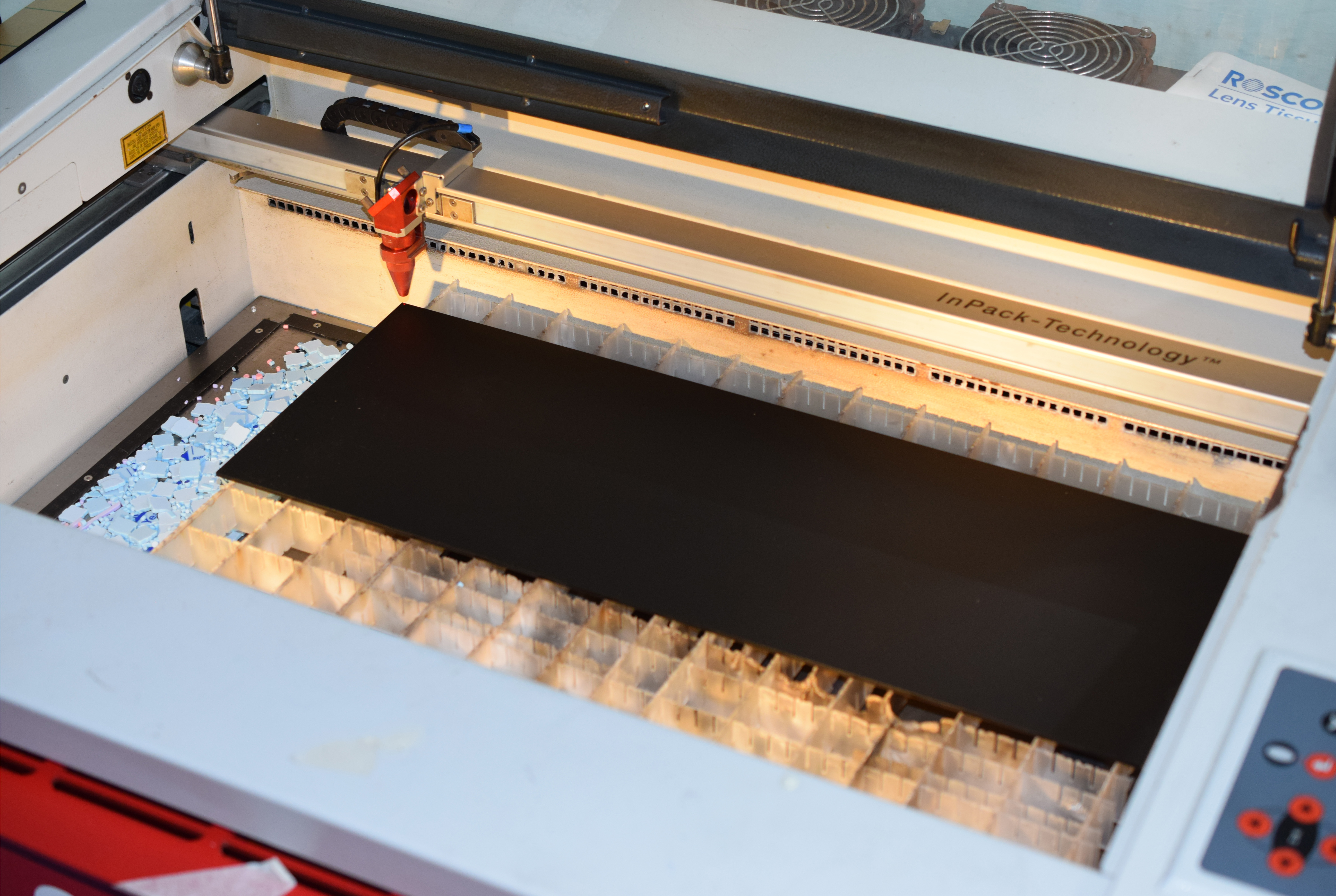

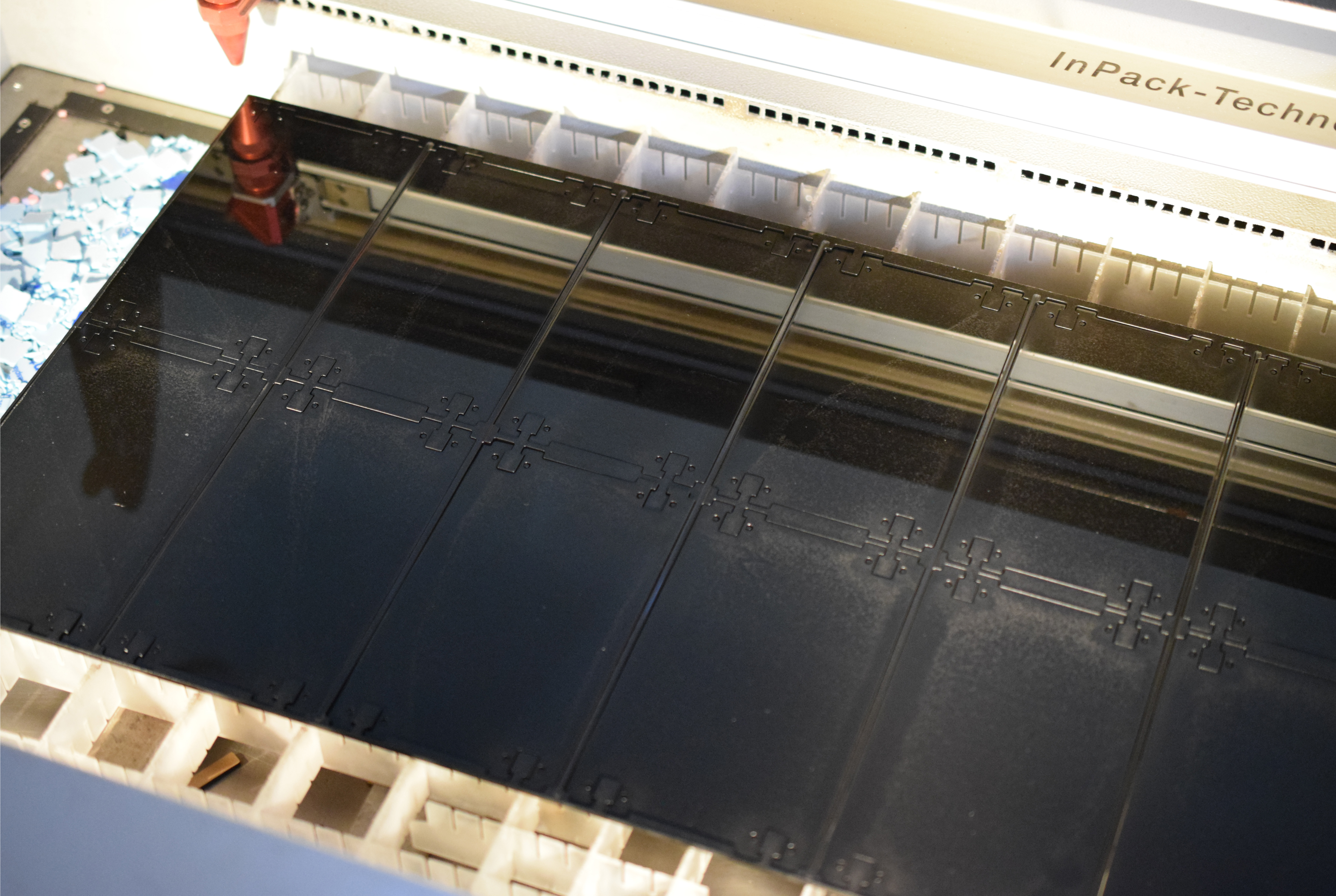

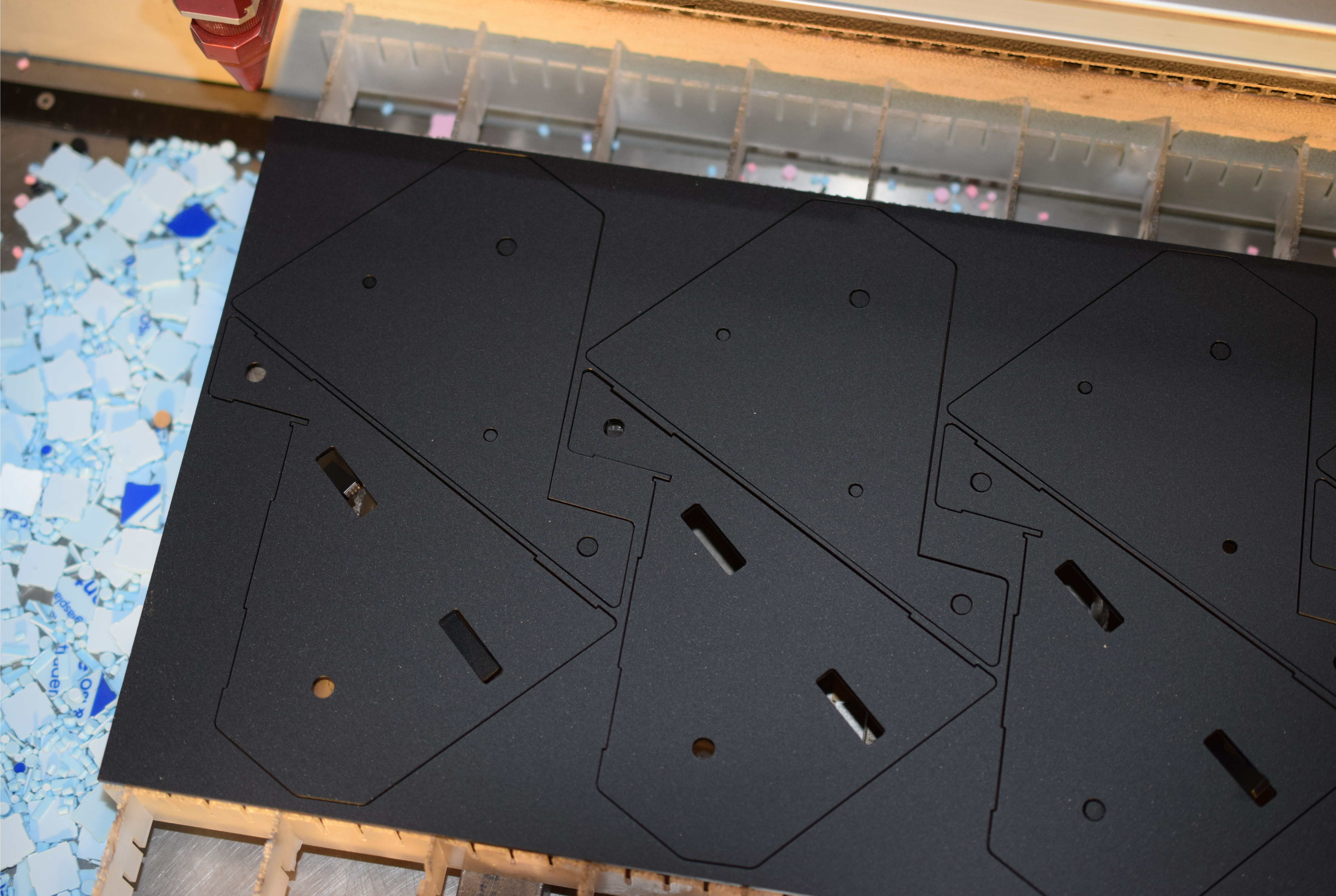

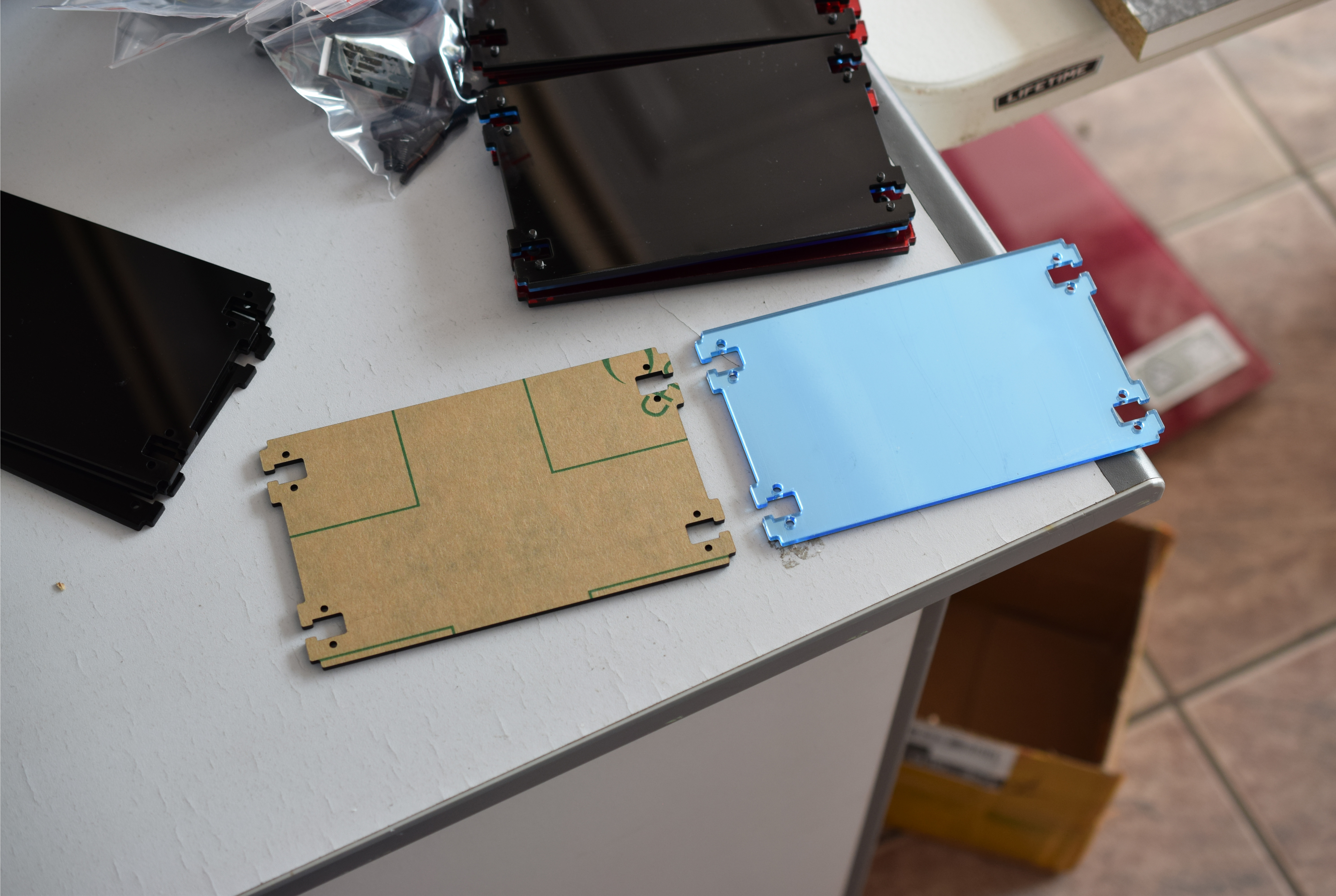

Cutting the Designs

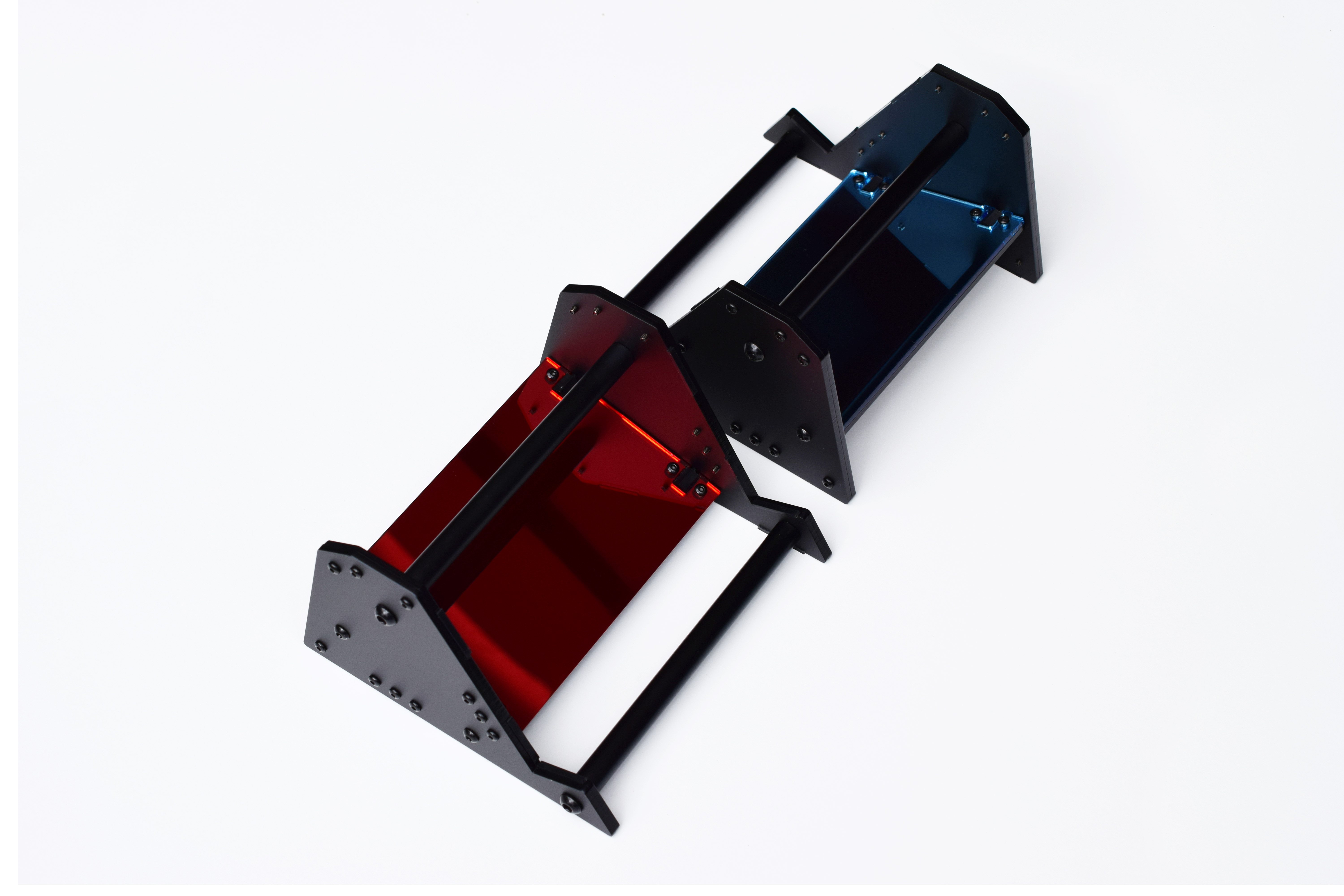

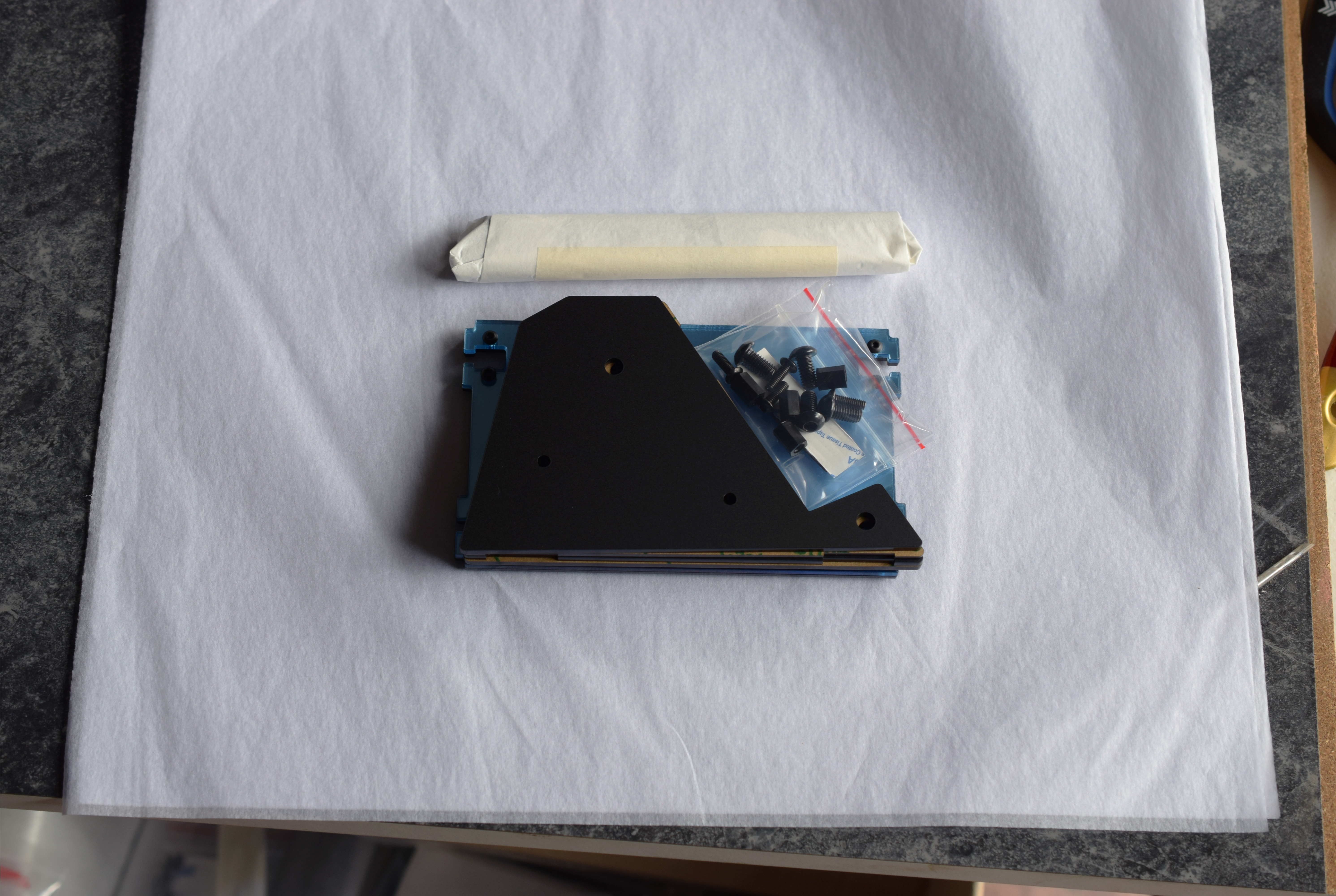

My Designer Stands have four different files that need to be cut. Depending on the colourway, I might need up to four different coloured sheets of material.

In this example I need three different pieces of material:

- Right and Left Side Pieces - Matte Black

- Top Base Piece - Mirror Blue

- Bottom Base Piece - Gloss Black

Cleaning Up the Off-Cuts

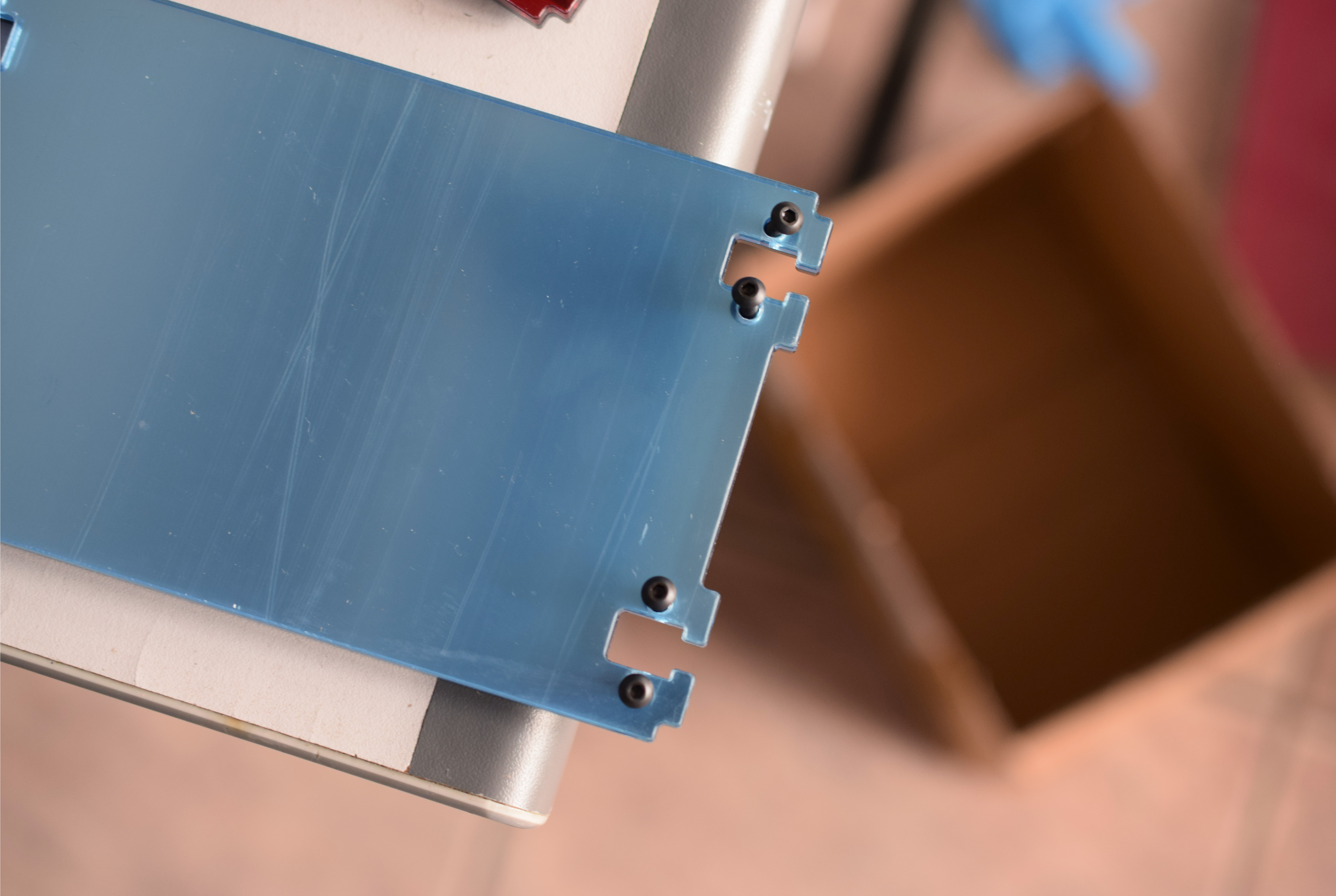

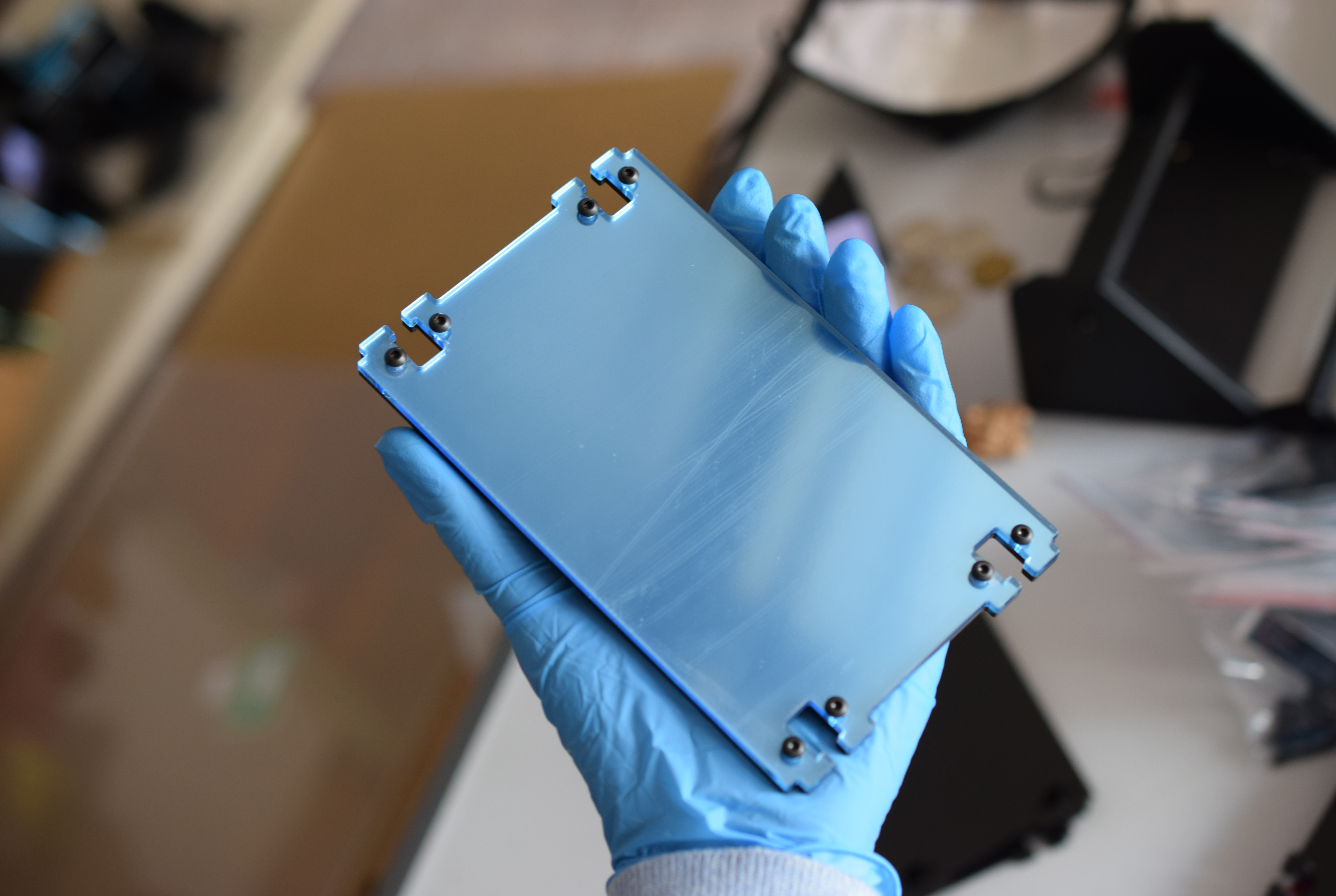

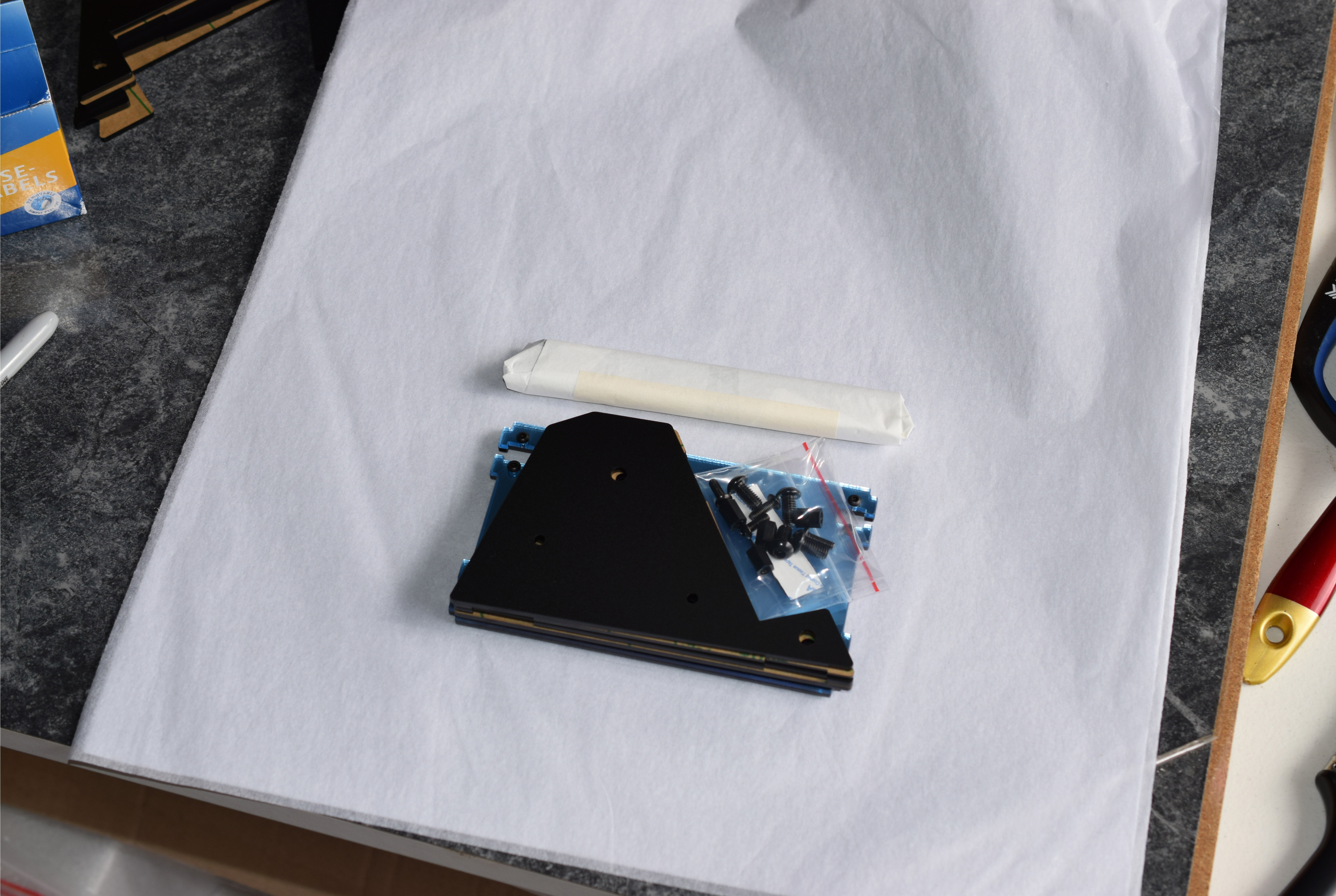

Assembling the Base Piece

For all the Stands I sell, I assemble the base pieces to make life easier for the end-user.

Admittedly , it is time consuming because there are several steps required:

- Peel off the protective film

- Align pieces in the correct orientation

- Install 8x M3 Screws into the acrylic

Packing the Hardware

Quite a bit of hardware needs to be arranged; I usually do this while the Laser Machine is running.

Packing and Counting:

- Adhesive Rubber Padding - Pack of Ten

- M4 Screws - Pack of Four

- M4 Nylon Standoff - Pack of Four

- M6 Screws - Pack of Four

- M6 Standoffs - Pack of Two

Once all the parts have been arranged, I finally get to wrap and pack everything together.

In the future, I aim to have correctly sized boxes to package my Stands into. Currently, the total package weighs roughly 400g.